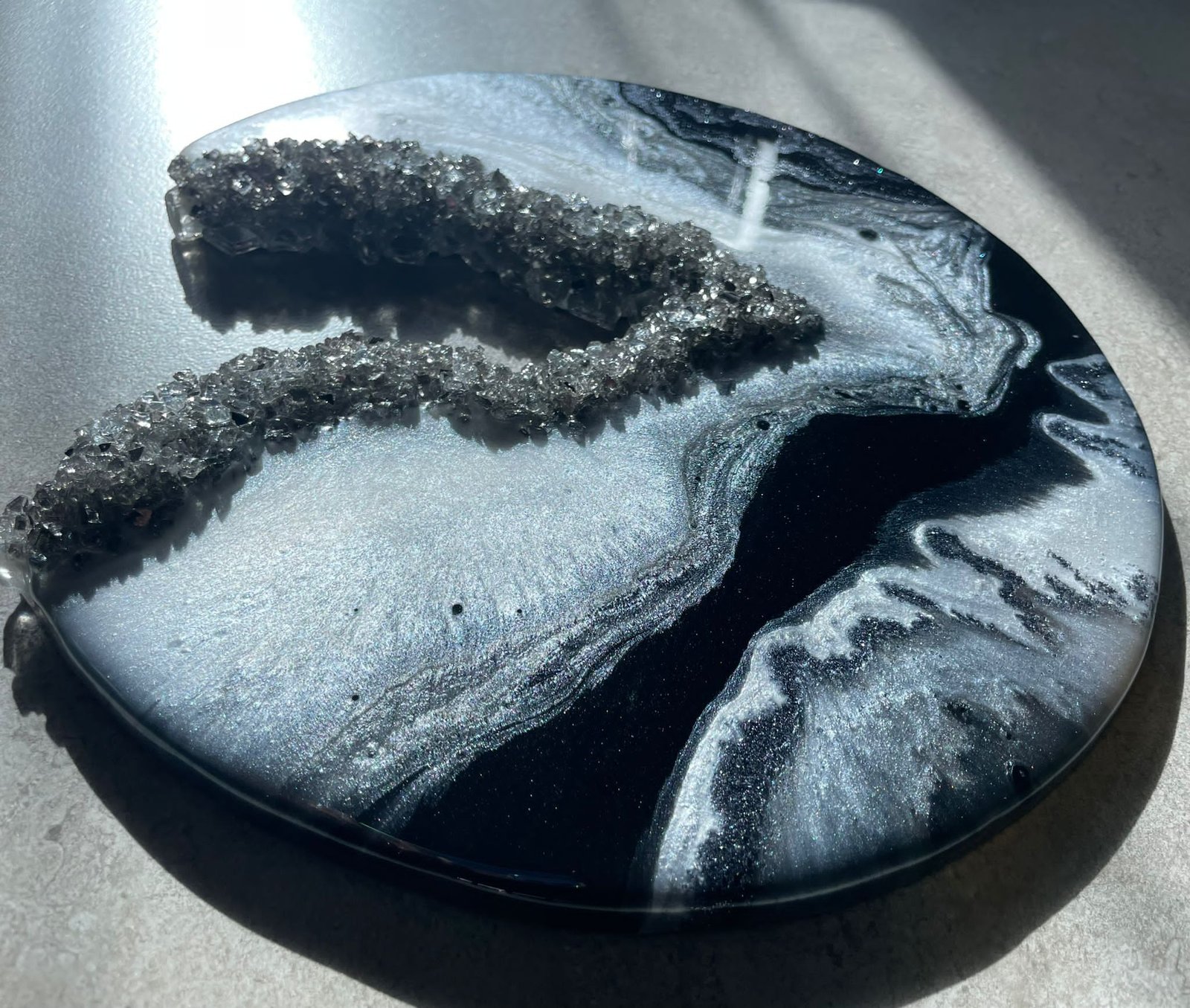

Pricing and Delivery: Your Tailored Artistic Solutions

I take into account various factors that can influence project costs. Factors such as size, dimensions, and the scope of the art/project installation are all considered when determining the charges.

To learn more about my pricing, kindly complete the form on my contact page, providing any size and colour specifications you may have. I will carefully review your request and send you a personalized quote that aligns perfectly with your needs.

Upon accepting the quotation and proceeding with the purchase and installation, a non-refundable 40% payment in advance will be required. This ensures a seamless and timely supply of my top-notch services.

Please note that delivery times can vary for each piece, depending on the number of pending orders and ongoing projects at the time of your order placement. Rest assured, I am committed to delivering your artistic solutions with utmost care and efficiency.

Have any questions? Please get in touch!

FAQs

1. What preparation is required for the surface?

For furniture pieces, panels or worktops, I ensure that all the necessary preparation is done before applying the epoxy. However, when working on flooring, having a solid sub-structure such as concrete is crucial. The surface must meet stringent high-quality standards; if this is not the case, it is recommended to apply a levelling compound layer before the epoxy preparation. This thoughtful approach ensures an impeccable and enduring finish for your project.

2. How long does the whole process take?

The duration of the entire process varies depending on the extent of preparation required, which may involve repairs, taping off, lifting stains, grinding and more. The preparation phase is typically the most time-consuming aspect, and understandably, epoxying a floor would take longer than a table due to the size difference. Once the surface is thoroughly prepared, I begin by applying the epoxy primer, which usually takes around 3 – 4 hours to settle, followed by the layer(s) of epoxy design. Approximately 24 hours later, I proceed with grinding the surface before expertly applying the topcoat/sealer. The overall time frame for the entire process usually ranges from 2 – 3 days, taking into consideration the size of the surface. Its important to note that the curing time is also influenced by the ambient temperature, which can vary significantly from season to season and from one home to another. To provide a helpful reference, I have outlined a guide to curing times below:

Temperature Curing time

25°c 7 days

20°c 10 days

15°c 15 days

10°c 20 days

5°c 30 days

Below is a guide to curing times:

Temperature Curing time

25°c 7 days

20°c 10 days

15°c 15 days

10°c 20 days

3. Can the epoxy be removed or replaced if I change my mind in the future?

Epoxy is renowned for creating a durable, impermeable surface that surpasses concrete or wood substrates in hardness. While it forms a strong bond, it is possible to re-coat an epoxy finish if desired.

However, to ensure a successful re-coating process, proper surface preparation is crucial. If the surface is not adequately prepared, a new epoxy layer may not adhere properly, leading to improper bonding with the existing surface. Rest assured, I take meticulous care in the preparation process to ensure seamless and effective re-coating, should you ever wish to make a change in the future.

4. Is the epoxy surface suitable and safe for surfaces where young children will be present?

Until the epoxy has cured or completely dried after application, which can take up to 2 weeks (depending on the ambient temperature), children should not be allowed near the area. It is also advisable to keep the area ventilated until the epoxy has dried, to avoid any fumes permeating other areas of your property. Once cured, epoxy does not pose any health risk to children or pets.

5. Does epoxy contain any allergens?

As with most industrial products, there is always a potential risk, however small, that someone could be allergic to dry or cured epoxy. It is always advisable to watch for signs of skin irritation or breathing issues when in an area that has recently been treated with epoxy. If you or someone in the property has displayed an allergic reaction to foods or other substances, we would recommend taking advice before proceeding with an epoxy surface.

6. Can the surface be susceptible to chipping, cracking or damage?

Although epoxy coatings themselves are resilient even in extreme temperatures, it’s essential to consider the underlying surface they are applied to, as it may be prone to cracking or damage, thereby impacting the epoxy’s performance.

Hence, it is crucial to ensure a sturdy sub-structure before applying the epoxy surface.

7. How well does the surface withstand wear and tear?

Epoxy surfaces demonstrate impressive water resistance and excellent wear resistance. To further safeguard against potential damage from sharp or abrasive materials, I recommend using clear, light-coloured wear pads or glides on furniture legs. This precaution helps protect the epoxy floor from sand, grit, and stains, especially on lighter shades of epoxy.

8. What is the recommended method for maintaining clean epoxy surfaces?

To effectively clean epoxy surfaces and remove dust, simply use a dry microfiber cloth, mop, or a vacuum. For thorough cleaning, a microfiber cloth or mop works wonders by lifting and removing dirt without leaving streaks. I suggest using a non-abrasive, low-foam, mild alkaline cleaner, like most trigger-spray bathroom or kitchen cleaners.

For tackling stains, applying a stain spray and wiping with a damp cloth should do the trick. It’s essential to address any stains promptly to prevent permanent marking of the surface. By following these cleaning practices, you can keep your epoxy surfaces looking pristine and well-maintained.